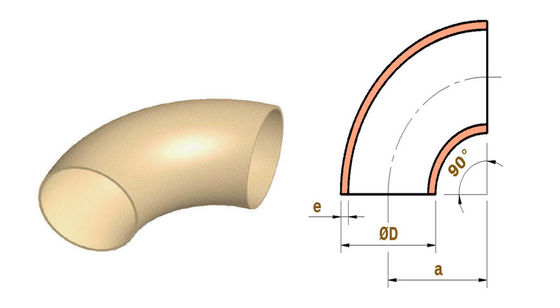

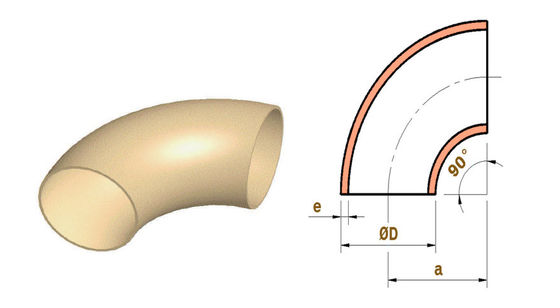

High Pressure Copper Nickel Elbow Fitting For Packaging In Wooden Case

| Package | Wooden Case | Standard | ASME, ANSI, DIN, JIS, Etc. |

|---|---|---|---|

| Shape | Elbow | Product Name | Copper Nickel Elbow |

| Size | Customized | Thickness | Customized |

| Connection | Welded | Pressure | High Pressure |

| Highlight | Copper Nickel Pipe Elbow,High Pressure Copper Nickel Elbow Fitting,Customized Copper Nickel Elbow Fitting |

||

Product Description:

Copper Nickel Elbow is a type of pipe fitting for connection with the purpose of changing the direction of flow. It can be applied to various areas in the industry such as water, gas and oil. It is made of copper nickel material which is highly durable and resistant to corrosion, and can be customized for different thicknesses to meet different needs. The welded connection ensures a highly reliable joint between two pipes. The use of copper nickel material ensures a safe, secure and leak free connection. It is an ideal choice for a wide range of applications.

Features:

- Product Name: Copper Nickel Elbow

- Processing Technology: Forging

- Standard: ASME, ANSI, DIN, JIS, Etc.

- Material: Copper Nickel

- MOQ: 1 Piece

- Thickness: Customized

Technical Parameters:

| Product Attribute | Parameter |

| Shape | Elbow |

| Surface Treatment | Polishing |

| Standard | ASME, ANSI, DIN, JIS, Etc. |

| Material | Copper Nickel |

| Application | Pipe Fitting |

| Connection | Welded |

| Package | Wooden Case |

| Pressure | High Pressure |

| Processing Technology | Forging |

| MOQ | 1 Piece |

Applications:

TOBO copper nickel elbow is a high quality pipe fitting product which is made of copper and nickel with polishing surface treatment. It is manufactured in China with high pressure, suitable for pipe fitting and welded connection. The product name is Copper Nickel Elbow. It has the following features: Brand Name: TOBO; Place of Origin: CHINA; Surface Treatment: Polishing; Pressure: High Pressure; Application: Pipe Fitting; Connection: Welded; Product Name: Copper Nickel Elbow.

Customization:

We offer custom Copper Nickel Elbow Fitting services to meet your unique needs. Our Copper Nickel Elbow Fitting are made from premium quality material and are manufactured under strict quality control. Our Copper Nickel Elbow Fitting are available with the following specifications:

Brand Name: TOBO

Place of Origin: CHINA

Package: Wooden Case

Connection: Welded

Material: Copper Nickel

Surface Treatment: Polishing

MOQ: 1 Piece

Support and Services:

Copper Nickel Elbow technical support and service includes:

- Assistance with product selection, installation, and maintenance.

- Technical advice on product applications and usage.

- Troubleshooting and problem solving.

- Replacement part ordering.

- On-site service and repair.

Packing and Shipping:

Copper Nickel Elbow Packaging and Shipping

The Copper Nickel Elbow is carefully packaged in a corrugated box with bubble wrap inside to ensure the product is safe during shipping. The box has the shipping label with address details printed on it. The entire package is then sealed with tape and shipped via reliable courier services.

FAQ:

- Q1: What is Copper Nickel Elbow?

- A1: Copper Nickel Elbow is a pipe fitting made of copper-nickel alloy manufactured by TOBO, a brand from China.

- Q2: What are the advantages of Copper Nickel Elbow?

- A2: Copper Nickel Elbow has excellent corrosion resistance, excellent strength and toughness, good ductility and weldability.

- Q3: What are the applications of Copper Nickel Elbow?

- A3: Copper Nickel Elbow is widely used in seawater systems, oil and gas industry, marine engineering and other industries.

- Q4: What kind of standards do Copper Nickel Elbow meet?

- A4: Copper Nickel Elbow meets multiple international standards such as ASTM, ANSI, DIN, JIS, ISO and GB.

- Q5: How to identify the quality of Copper Nickel Elbow?

- A5: The quality of Copper Nickel Elbow can be identified through its material quality, surface treatment, dimensional accuracy, mechanical properties and chemical composition.