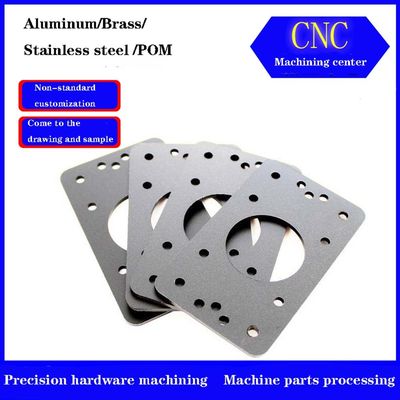

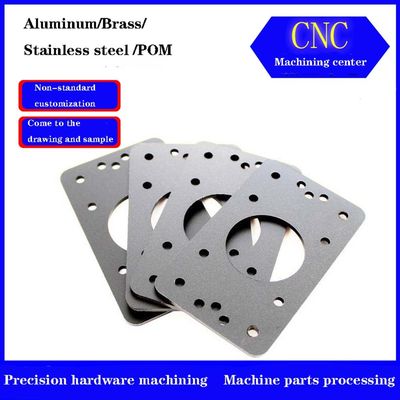

Copper Nickel High Precision Custom CNC Machined Parts Hardware New Energy

| Place of Origin | China |

|---|---|

| Brand Name | TOBO |

| Certification | API/ SGS |

| Model Number | 90/10 |

| Minimum Order Quantity | 10ton |

| Price | Negotiable according to quantity |

| Packaging Details | Standard seaworthy export package or as required |

| Delivery Time | 7-45 workdays |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 300000 tons per month |

| Length | Required | Shape | Required |

|---|---|---|---|

| Price Term | CIF CFR FOB Ex-Work | Package | Standard Seaworthy Export Package Or As Required |

| Wall Thickness | Customized | Specification | Customized |

| Product Name | Copper Nickel High Precision Custom Cnc Machined Parts Hardware New Energy | Grade | Copper Foil |

| Highlight | New Energy Copper Nickel Hardware,Copper Nickel Custom CNC Machined Parts |

||

Copper Nickel High Precision Custom CNC Machined Parts Hardware New Energy

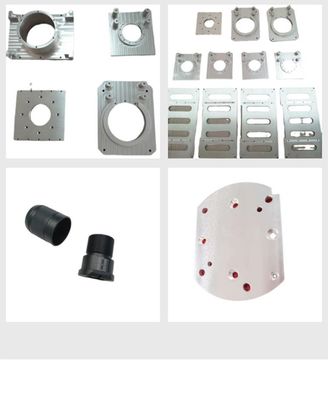

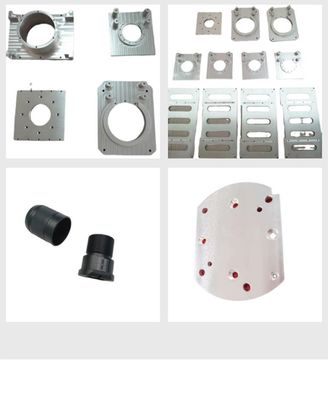

CNC Milling

CNC Drilling

What is precision CNC machining?

CNC precision machining involves the process of cutting and molding raw materials to create parts with tight tolerances and complex geometric details. Computer aided design (CAD) and Computer aided Manufacturing (CAM) blueprints help guide the proper cutting process. These programs are essential in the design phase as they often contain detailed 3D Outlines to ensure successful construction of the part.

High-precision machining now plays an important role in manufacturing and requires the cooperation of highly skilled designers and engineers. Designers first create designs and then turn them into manufacturing instructions. The mechanic then sends the final coded instructions of the machine language to the CNC device to begin the manufacturing process.

In addition, some core areas require precision machining to produce components that are immediately functional and can be assembled well, such as surgical instruments, aerospace parts, automotive parts, optical parts, etc. The use of advanced precision machine tools in precision machining will facilitate the creation of complex parts with complex geometrics. A typical CNC machine can achieve tolerances of +/- 0.005 inches. However, when using CNC precision machining, tolerances of +/ -0.002 inches to +/ -0.0002 inches can be achieved.

Optical instrument, Automotive, Electronic device, Digital communication, UAV, Aerospace, Bicycle, Pneumatic tools, Hydraulic, Automatic Mechanical, etc

|

1. Are you trading company or manufacturer ?

We are manufacturer ,You can see the Alibaba certification.

2. How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q4 : How to deal with surface treatment problems?

Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

4. Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but need pay the cost of freight.

5. What is your terms of payment ?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment.