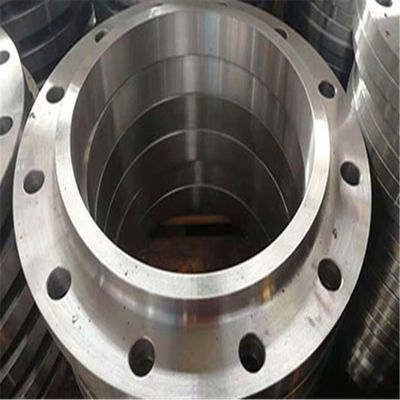

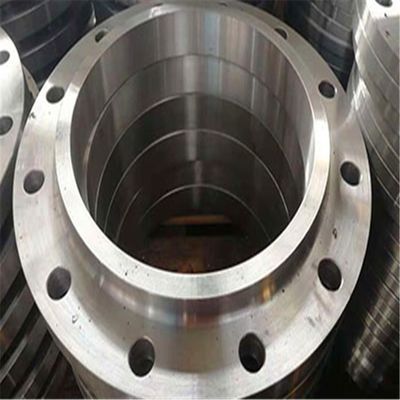

Forging Socket Weld Raised Face Flange 1/2''-24'' ASMEB16.5

| Product Name | Factory Direct Copper-nickel Flanges Can Be Customized In Various Models And Sizes | Product Type | Socket Welded Flange |

|---|---|---|---|

| Size | 1/2''-24'' | DN15-DN1500 | 15-1500 |

| Manufacturing Process | Forging | Type | Forged Steel |

| Standard | ASMEB16.5 | Often Used Of | PN≤10.0MPa,DN≤40 |

| Highlight | Forging socket weld raised face flange,socket weld raised face flange 1/2'',24'' socket weld orifice flange |

||

Factory direct copper-nickel flanges can be customized in various models and sizes

| Product Name | |

| Standard | ASME/ANSI B16.5 |

| Size | 1/2’’~24’’ |

| Pressure Rate | 150lb to 2500lb |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Material | Forged steel |

|

Allloy steel flange

|

ASTM A182 F5; F11;F22;F91;F51 ASTM A350 LF1; LF2; A350 LF3 ;LF4;LF6;LF8 |

|

Stainless Steel flange

|

ASTM A182 F304/304H/304L ASTM A182 F316/316H/316L ASTM A182 F321/321H ASTM A182 F347/347HPN≤10.0MPa,DN≤40 |

|

Nickel Alloys Flanges

|

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276 |

| Copper Alloys Flange | Copper, Brass & Gunmetal |

| Manufacture Standard |

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 |

| Package | Wooden cases, pallets, nylon bags or according to the customers' requirements |

| MOQ | 1pcs |

| Delivery time | 10-100 days depending on quantity |

| Payment terms | T/T or Western Union or LC |

| Shipment | FCA Tianjin/Shanghai, CFR, CIF, etc |

| Application | Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc |

| Remarks | Other materials and drawings are available. |

Another function of the socket weld flange is the socket inside the shoulder. The shoulder allows the pipe to slide onto the flange until it touches the shoulder to ensure proper placement of the pipe on the flange. After the pipe touches the shoulder, the welder can attach the flange to the pipe by butt welding around the socket. The pipe is the same height as the shoulder in the socket and can provide the same strength as the internal weld of the sliding flange, but without the grinding associated with the internal weld.

![]()

![]()

![]()

By eliminating the need for internal welding, socket welding flanges save assembly time while maintaining the same strong connection. By matching the inner hole of the socket to the inner diameter of the pipe, thicker sockets provide optimal flow and a smooth transition in case of mismatches. Socket welding flanges can be made of mild steel and stainless steel and can be used for food grade and non-food grade piping. Flanges are also suitable for high and low pressure applications.